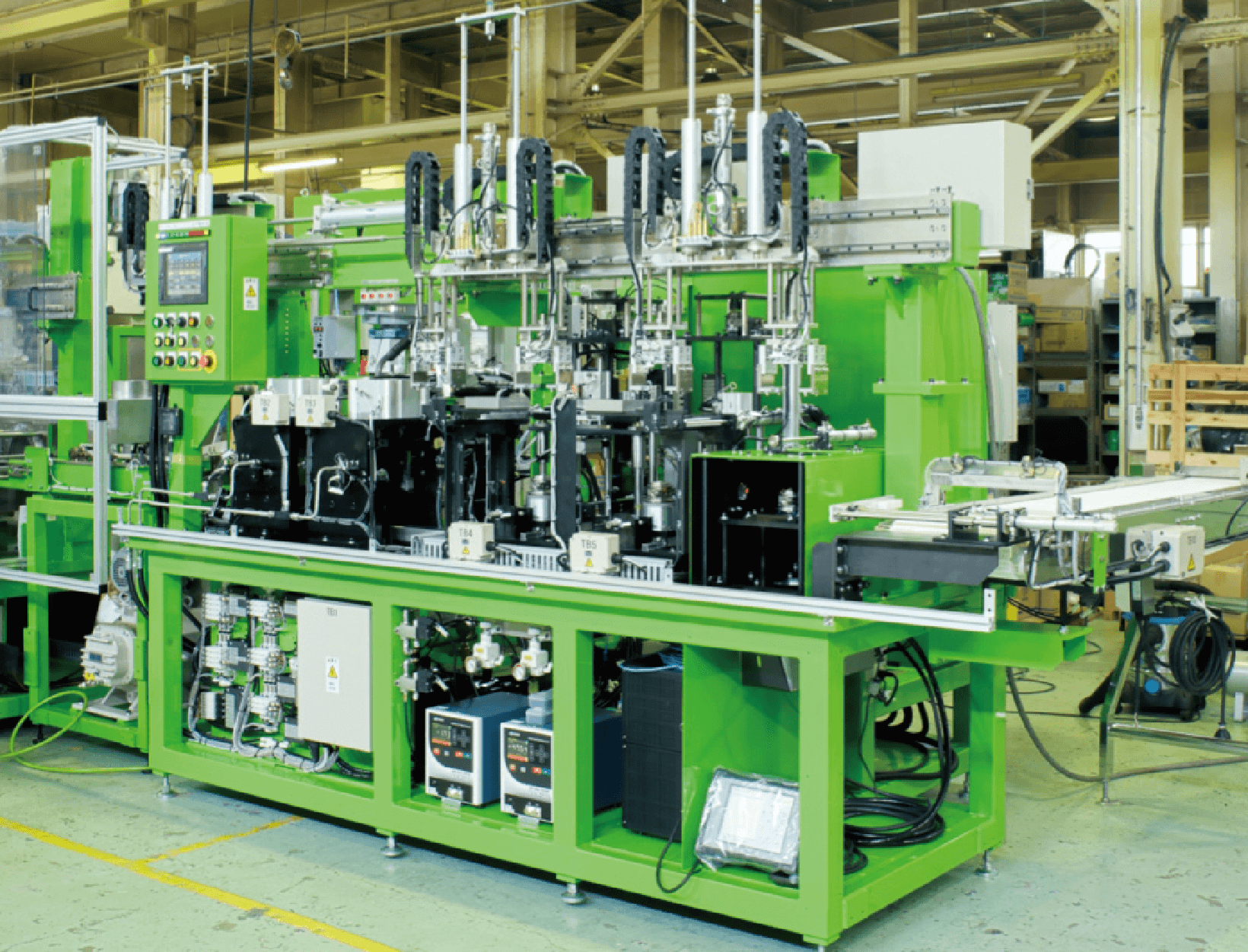

Case 01:Processing machine for bracket

This facility has 2 index tables consists of 8 stations, and br acket has been chamfered, drilled and tapped at each station. Space saving has been realized by process consolidation.

Target workpiece:Aluminum

Cycle time:12sec/piece

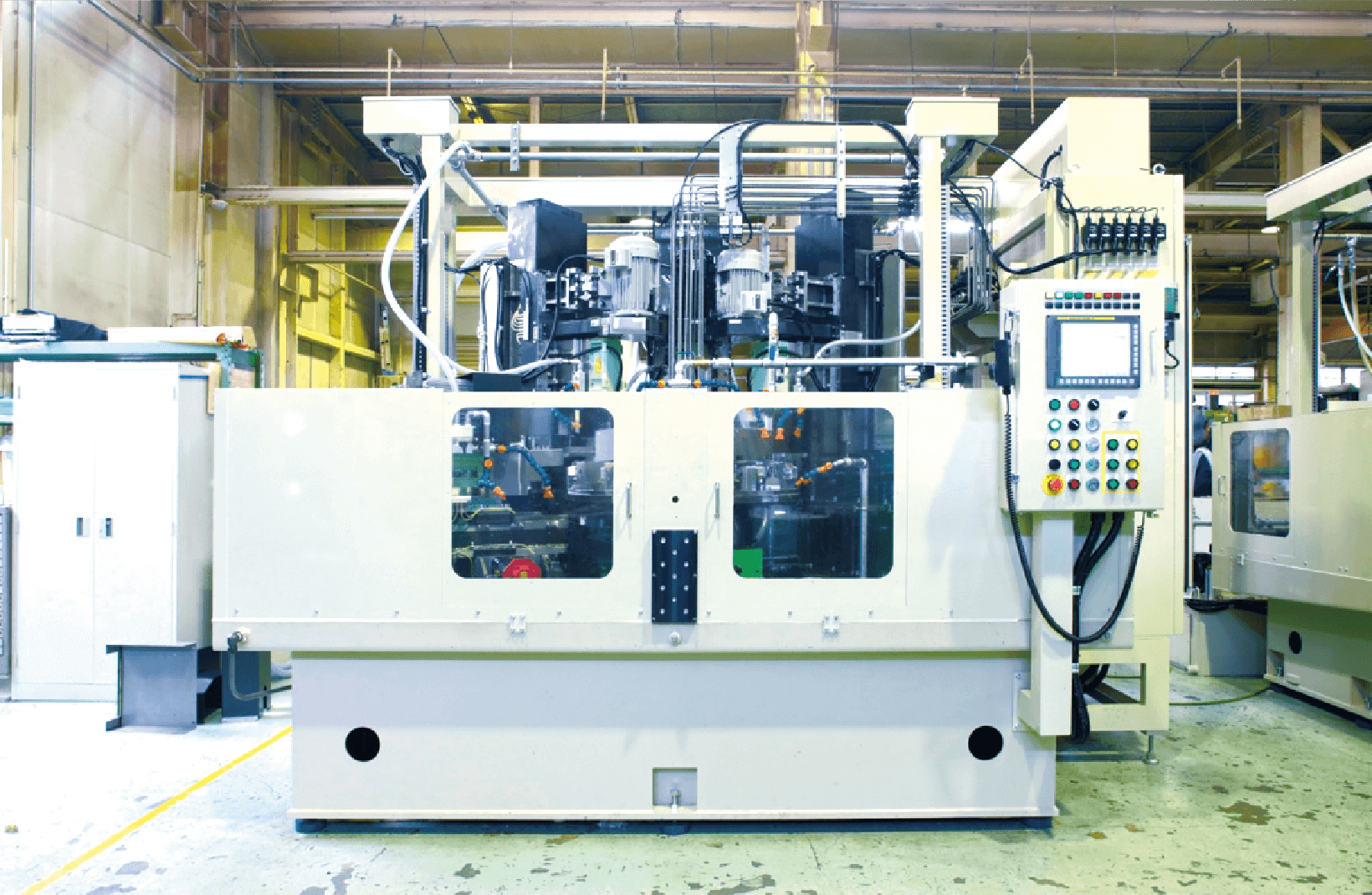

Case 02:Processing machine for joint

This facility has 6 stations of index table, and each station copes with all joint processing. A variety of

workpieces have been processed flexibly in 5 stations of X, Y, Z axis controlled NC slide.

Target workpiece:S25C

Cycle time:15sec/piece

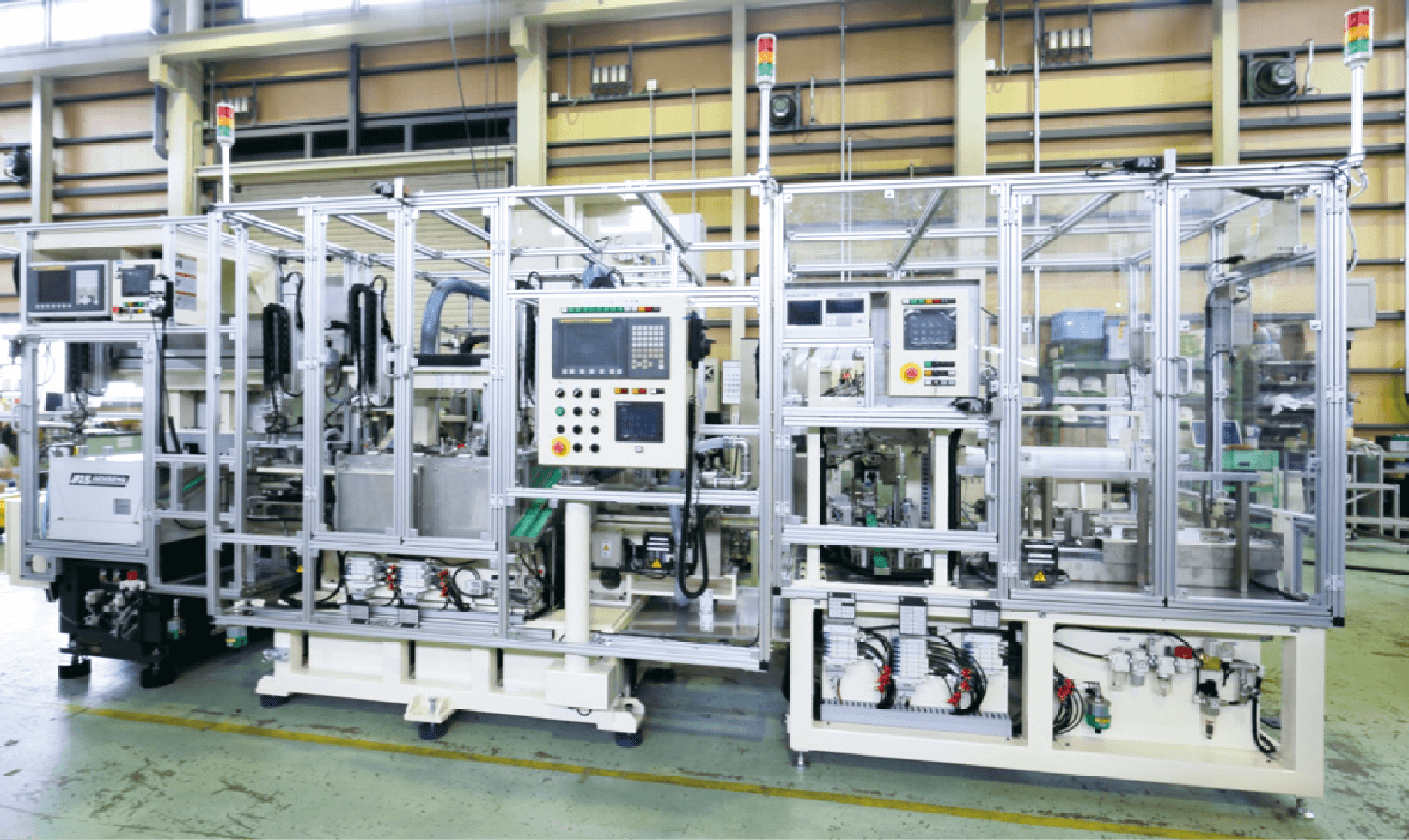

Case 03:Deburring washing machine for sleeve / Outer diameter measurement palletizer

Deburring by brash, washing, outer diameter measurement and se tting workpiece into pallet can be done by this facility consistently. A combination of orthogonal robot can cope with short cycle.

Target workpiece:Aluminum

Cycle time:11sec/piece

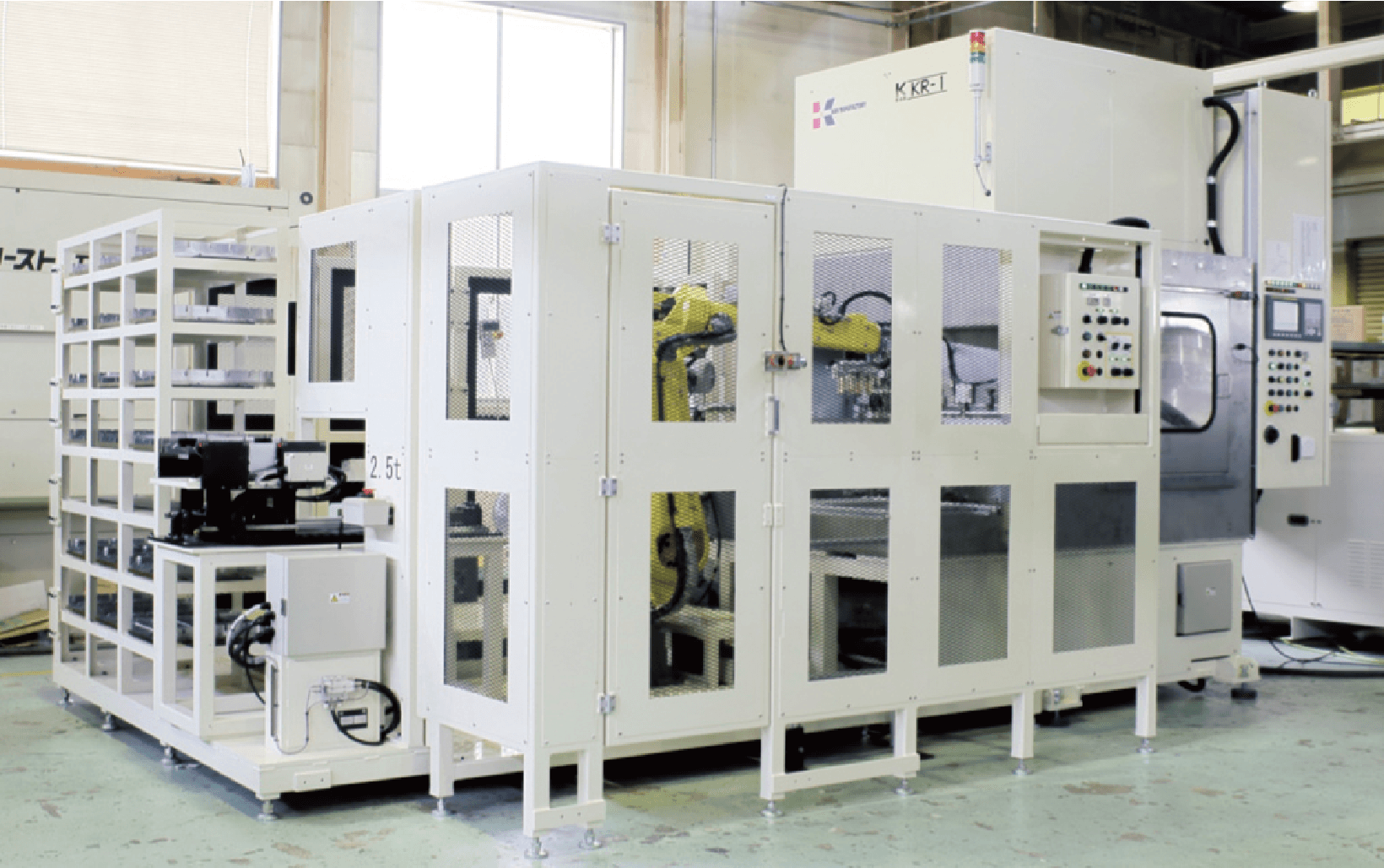

Case04:Deburring washing machine for shaft (with robot transport funct ion)

Deburring, high press ure washing and desorption of workpiece are car ried out by this machine.

Automation of workpiece desorption using an articulated robot has realized a labor saving.

Target workpiece:SAE5140H

Cycle time:30sec/piece

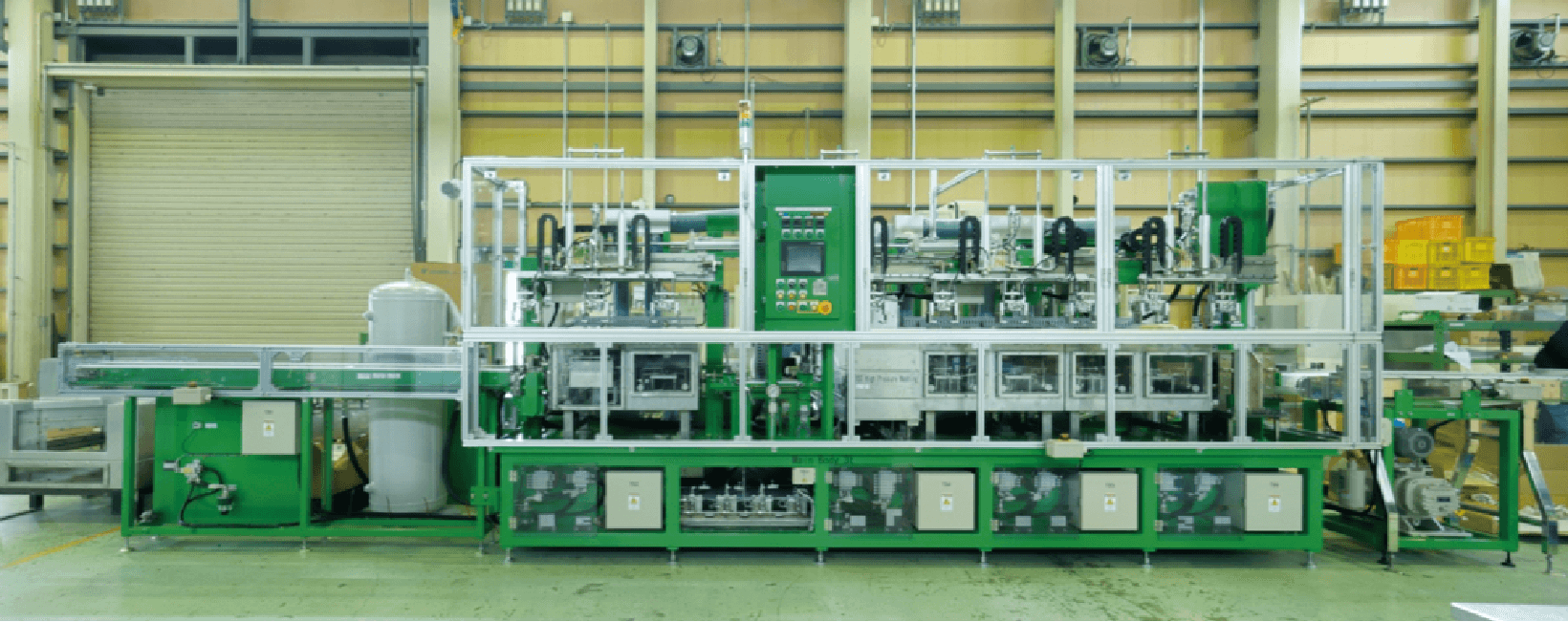

Case05:High pressure washing / Air blowing / Anti rust treatment / Vacuum drying device

This device is loader transport type washing machine, and has 4 stations of washing and air blowing. It copes with precise washing and short cycle by changing washing method at each station.

Target workpiece:FCD

Cycle time:35sec/piece

Case06:Press fitting / Leak / Laser marking machine

This facility is made for cap press fitting, leak inspection and laser marking. P/P transport has realized automation and reducing of man-hours.

Target workpiece:FCD

Cycle time:35sec/piece